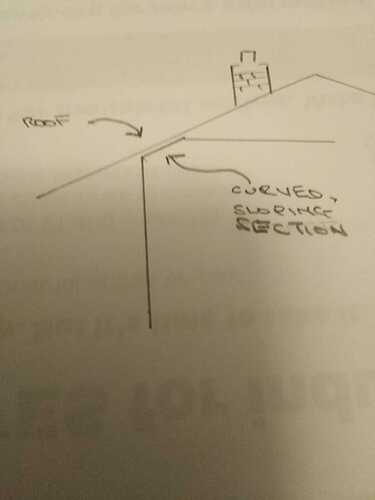

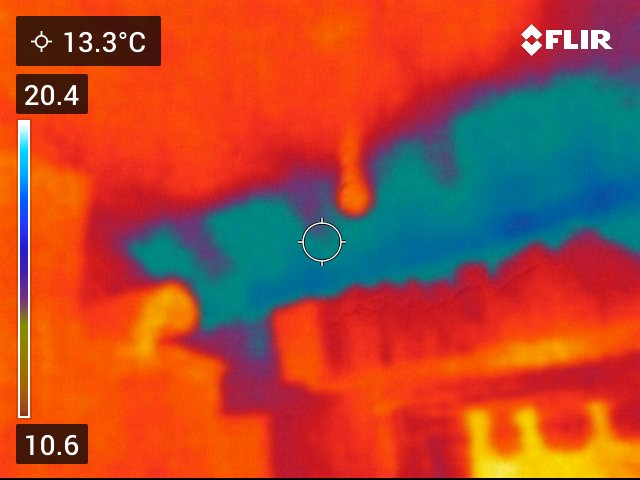

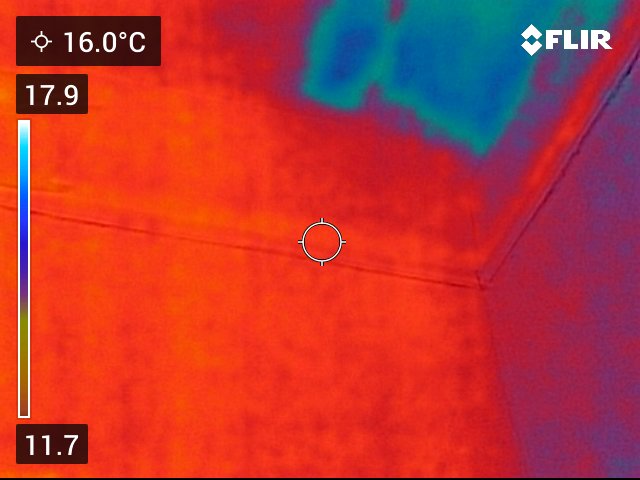

We’ve got curved sections along the external edge of all upstairs ceilings (presumably a compromise between extent of roof and ceiling heights) - see sketch. This was outside the reach of the loft insulation, so I’ve had a strip of insulation (not v thick) inserted into the space between the roof-tiles and this curved surface; however the heat camera still shows a chilly (blue) strip inside, ie 10deg colder than the rest of the ceiling - see heat-photo. Is there a way to insulate this from the inside? (Or possibly not, because of condensation risks…)

A 10°C difference too great to be ignored and will lead to mould or even wet rot if not addressed.

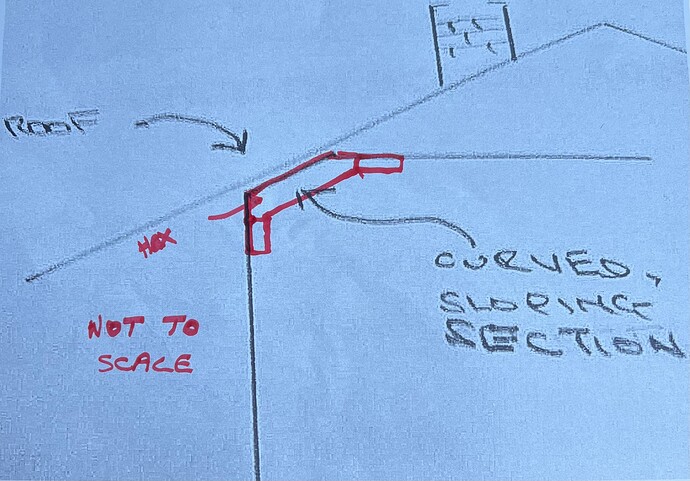

This can be addressed by treating the inside with a section of IWI. The extent of the IWI is dictated by your concern about thermal bridging (1 meter overlap of existing “good” insulation) and the cosmetics of having extended IWI cover.

Other insulating materials are available but my example uses PIR or other rigid board.

Decide on the extent of overlap that you want/need. Strip any wallpaper that would be covered and wash off the paste. Buy an appropriate amount of 100mm board, perhaps bonded to plasterboard, minus 250mm. Also buy 250mm (or more) board to cover the cold strip and approx 250mm of the ceiling and wall. Now the trickiest part. The 250mm board needs to be cut into an irregular hexagonal shape to fit the cold strip, a small overlap and leave an upstand to butt to the 100mm overlap board. Fix the boards with plastic or other non metallic fittings, taping all joints.

In practice the overlap of the wall would probably look best down to and around the window lintel and a corresponding height along the wall(s). You might choose to overlap the ceiling by a corresponding amount due to the aesthetics of symmetry.

Hi again Tim. Thanks. Yes we’ve had black mould on all these curved edges of upstairs ceilings; that’s what prompted me to follow the advice of a local roofer (of good repute) to have a strip of installation installed from the outside. That appears to have eliminated the mould (after cleaning and a coat of Stainblock paint), but it’s still showing up cold on the camera - not surprising, I suppose, since the strip of insulation could only be of limited thickness.

Unfortunately you’ve completely lost me from hexagonal strips onwards…! In principle, are we talking about affixing PIR board directly on to the cold strip, with overlap to adjacent (warmer) wall and ceiling?

The centre piece is cut as a hexagon, with the wall and ceiling pieces abutting. I suggest a bigger overlap than the quick sketch implies.

Aha…got it now, thanks, that’s really useful, tho tricky as you say. Would that be airtightness tape along all joints? Also: boards fixed along the cold sections and along the adjacent main (horizontal) ceiling might not always be a close fit, because these cold, sloping sections are curved along the top, ie along the stretch where they meet the main ceiling… Does this raise the risk of dew-point and resulting condensation behind any not-close-fitting board?

If you cannot cut the insulation to give a snug fit to the curve (a very long shot I have to admit) then it is very important not to let any air from the house get into the void. I would therefore use airtightness tape along all joins between panels and between insulation and existing wall/ceiling.

You also need to ensure that the void can “breath” to the roof space so that any trapped moisture can escape.

It should not matter to the structure or comfort of the house that there is a small area that doesn’t breathe.

If the curve is considerable it may be worth using a flexible insulation board such as some wood fibre boards, for which an increased thickness will be required.

Thanks, much appreciated, I’ll have a go at one of the guilty areas.

…two further q’s please,

- what thicknesses of board? Maybe 50mm for the actual cold strips, abutting to 12mm for the overlap strips?

- can I/should I render/plaster over afterwards, mainly for cosmetic reasons? Or maybe, just paint?

We put 25mm of celotex between rafters (leaving an air gap between insulation and roofing felt) and 100mm below. We ran the celotex into the loft space and down to the EWI.

Good stuff… Was this on top of/in addition to ‘regular’ insulation of floor of loft, ie between joists, or was it instead of that? Is this an example of what’s called a ‘warm roof’?

In my example above I specify 250mm for the cold strip and 100mm for the overlap although I expect a Passivhaus professional would specify 250-300mm for the whole thing.

Plastering over will protect the insulation from minor to medium knocks. Insulation tends not to be very strong. It’s all those air gaps.

Yes, a warm roof is one where the roof space in included in the thermal envelope. It should have the equivalent of 250-300mm glass fibre. For some reason the British press always assume glass fibre. When built new it is relatively easy to fit the insulation contiguously with the wall insulation.

The celotex doesn’t extend up to the roof ridge, but about 500mm above the loft floor. We have ‘regular’ insulation on the floor of the loft and therefore have a cold roof. It’s by no means perfect, but we have continuity in insulation. And yes, the celotex is plasterboarded and skimmed over. In retrospect and following Grenfell I might have gone for rockwool or wood fibre instead of celotex, but too late now!

The time taken to evacuate a house is seconds (assuming able bodied). The time taken to evacuate Grenfell was hours. Don’t worry about the Celotex.

If you haven’t done so already plan your evacuation routes and practice them blindfolded. The children will love the fun.

What are people’s thoughts about cutting the boards square and then foaming the gaps?

I’m midway through insulating a protruding box window. I’m using PIR and have left a 10mm gap all the way round before filling with foam, trimming then taping. Albeit it’s square I find that leaving fillable gap is more reassuring than relying on cutting accuracy.

I’m using Illbruck FM330 foam which was recommended on a carbon coop training session that I attended in York a few years ago.

Foam is a simple way to fill relatively small gaps. To fill something the length of an insulation board from one end isn’t practical. I have tried to do the same with PVC window cill to insulate the cavities under the window frame but thermal images show gaps. I had flexible “rubber” pipe attached to my spray gun and still I couldn’t fill a confined space.

… I’m failing at the kit-assembly stage here!, surprised to discover that I can’t find all-plastic fixings anywhere…

I found a good selection on the Internet… in America!

How about

not 100% plastic but insulated.