I thought that it might be helpful to members to log how an application to the Boiler Upgrade Scheme (BUS) for an air source heat pump progresses. As you may know it opened on Monday 23 May and applications are made by installers who are issued a voucher of £5,000 or £6,000.

I have been pursuing three installers this year and only one has produced the necessary information available for an application. They visited, undertaken a room-by-room heat loss assessments and hot water requirements, examined the current radiators and pipework, and the potential space for the external unit and cylinder. They have produced detailed calculations on how the installation would meet the heating requirements of the house using a flow temperature of 50℃ at an outside temperature of -2℃. Their proposal involves upgrading most of the radiators (some to K3 size) to ensure that they met 100% of the heat loss, although it was a very close call in some rooms. Two in the basement had been deliberately undersized previously. The installer was reluctant to design the system for 55℃ and it wouldn’t have reduced the requirement for radiator upgrades much and might have cost about 5% more to run. They quite reasonably wanted a little bit of give in the output to ensure that we would be warm on the coldest days. Some of the heat loss calculations were queried and changed.

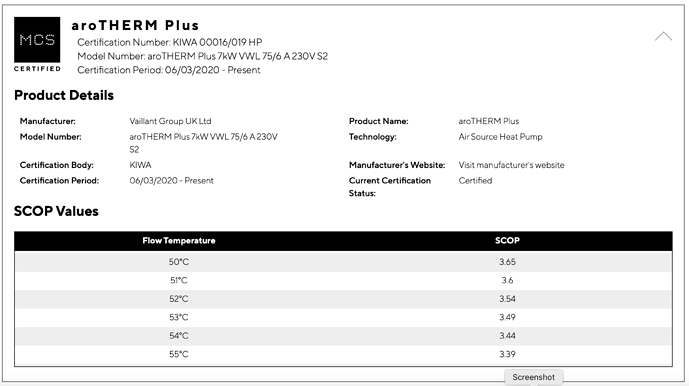

The system proposed is a 7kW Vaillant heat pump with a Vaillant cylinder and smart controls. Existing 10mm microbore pipework serving the bedrooms is being retained as the advice from the installer is that it will work given that the output of each radiator is below 400w. At 50℃ the SCOP is 3.65. The running costs, from my calculations, a little cheaper than the existing gas boiler and substantially cheaper using my Tesla Energy Plan tariff which is currently 10.97p per kWh.

We will see how Ofgem manages the administration. Of course there will only be c30,000 vouchers per year against the background of c1.7 million gas boiler installations.

That is unbelievably high for a SCOP, particularly as the system will be under utilised in the summer and working hard in the winter. Maybe they are quoting the SCOP for an ideal setup, i.e. flow temperature of 35-40°C, perhaps with underfloor heating.

Hi Tim, you are right in that it is for an ideal setup for a flow temperature of 50℃ and the figure is for heating only but this is the MCS certification for the heat pump.

I’m sure that there will be some work to do to optimise the system!

Thanks Julian

Hi Julian,

Thanks for sharing this, it’s helpful and interesting to have an insight into the application process.

Did the installer say why the calculations only cover heating rather than hot water? It seems odd, given that to qualify for BUS funding the system has to supply energy for both, not just one, and the water temperature would need to be higher than 50°, further affecting the COP.

I’ve not looked at the MCS assessment criteria, bar the need for individual room calcs (which Trystan Lea’s JavaScript tool is great for), so perhaps it’s purely driven by those?

I also wonder if there are any boiler donation schemes.

We are removing our multipoint, having gone ASHP, however the boiler is only a few years old and very efficient as these things go. It seems like it would be good to have it reused by someone else who needs it.

Hi John

I’m pleased that you have found my post useful.

I don’t have an up to date ‘Heat Pump Performance Estimate’ from the installer at the moment but the form would give the SCOP for the hot water as well as the heating . From the earlier version it looks like a standard form required for the BUS and derived from the RHI form of the same name.

Julian

Hi Simon

I have been looking into recycling the existing gas boiler which is in good condition. My gas maintenance engineer told me that there isn’t much financial value in used combi boilers but I am hoping that he might be able to help find a good home for it. There are some postings on eBay with various values.

I also have in mind recycling it to a friend whose boiler needs replacing but who doesn’t want to pursue a heat pump at the moment. There must be quite a few people in that position and obviously the last thing that we want to see is them fitting a new boiler with a life of 10-15 years.

Julian

Interesting… Octopus told me that they can’t work with Microfibre (10mm) pipes - its a new build so I didn’t have a lot of choice!

I was in touch with Octopus last month and they told me that they plan to address issues of working with microbore pipework with their heat pump roll-out. I understand from other sources that microbore can lead to problems with flow and noise. In my situation the higher output radiators are served by 15mm pipework and only the lower output radiators have 10mm pipework. It would be different if all radiators were served with microbore. Another thing to bear in mind is that the plastic microbore has a smaller inside diameter.

Julian

I heard back from the installer and, using the figures from MCS, the SCOP for heating is 3.65 and for hot water it is 1.75. This gives a combined SCOP, based on my usage which is based on the latest EPC, of 2.97. The challenge is going to be how to maximise these figures in the detailed design and real life use.

There are several versions of microbore, in certain circumstances some might be ok with heat pumps.

As a matter of interest is the 10mm the internal or external diameter? If external you probably have a 7 - 7.5mm internal, half the “normal” and therefore about a quarter of the cross section.

Flow rate is a function of internal cross section area (allowing flow), internal surface area (causes drag), the texture/smoothness of the internal surface (a drag coefficient) and the pressure.

If the system will take the pressure you can get any flow rate you like with any diameter/texture pipe and it is here that expert advice comes it. You definitely don’t want a high pressure leak or even explosion anywhere.

Just received a request to give consent to my installer’s application to the BUS scheme which I did by online form. The turnaround from the application has been one week. Ofgem will now process the application. I was encouraged by the application reference number which is well below 30,000, roughly the annual capacity for the funding.

That’s my thinking exactly. I’m not really looking for payment (though won;t turn it down), but don;t want to waste a perfectly good boiler, with all it’s embedded carbon, when it could be better for someone else.

My installer got the approval for a BUS grant of £5,000 on 23 June so we are getting set to install within the three month timeframe allowed. Quite a quick turnaround for a decision - one month after the scheme opened.

The work will involve installing a 7kW Vaillant ASHP, a 250l Vaillant hot water cylinder, Vaillant Senso smart controls, and quite a number of radiator upgrades to achieve a target flow temperature of 50℃ with a SCOP of 3.65. The microbore pipework is being retained for now as it only serves relatively low output radiators.

Congratulations.

Have you tried running your current boiler at similarly low flow temperatures?

Hi Tim

It’s been running at 55℃ since the end of last year and the house has been comfortable but it has been a mild winter. The smart thermostat has been set at 18℃ through the day and 15℃ overnight, with the temperature boosted when necessary. The larger radiators planned should work well with lower flow temperatures. I anticipate changing the thermostat temperatures to allow for lower outputs for longer periods eg having an additional (warming up) temperature of say 16.5℃ just before the beginning of the day to avoid a steep rise in output from the heat pump.

Really interesting about the microbore pipework - I applied to Octopus to have an ASHP fitting to my brand new build house and they told me they cannot (at the moment at least) support it, so I would be interested to know how you get on.

An update focusing on the Boiler Upgrade Scheme. The heat pump and cylinder were installed, some radiators swapped over with one radiator added. The pipework in the living room was changed from 10mm to 15mm pipework. It all took four days this week with three plumbers working on the job plus two electricians for a day.

The installer provided me with invoices the next day and asked me to pay £5,000 less to take account of the grant.

In terms of timetable this has gone very swiftly but not without a huge amount of work in procuring the system. I started that process last July! The delay was mostly due to the availability of kit.

The boiler, a Vaillant 838 Ecotec Plus and the redundant radiators are now on eBay waiting for a new home.

Wow - that’s great! Would you mind sharing the details of the firm(s) you used please?

It looks as though you have the advantage of a good sized plant room. How much of what we see is ASHP specific?

I think I see an MVHR edging into the second picture too.