Sorry for writing all of this down in one go, and I would appreciate your input just to help me understand and not miss a trick and get unwittingly some cold bridges added above and under incredibly expensive new doors. Thanks.

Lintels:

If you anticipate further slight movement between leaves go for 2 single brick thick lintels with insulation between. Use concrete, not RSJs, to reduce conductivity and possible condensation..

If you believe that the leaves are sufficiently bonded to move in unison use insulated double depth lintels.

Also the lintels need to be significantly longer than the arches originally used. Those arches are clearly too short. Precise measurements from your structural engineer.

Thresholds:

Compac foam is structural. EPS is not. I expect your builder is thinking of EPS in a cavity with support from inner and outer wall leaves for the threshold.

As the specified size doesn’t match a standard one there are two possible courses of action.

Either:

- Ask your architect about using the nearest sizes, up or down.

- Buy the next size up from your requirements and cut to size. You will probably also find some ad hoc use for the offcuts. Or maybe you can find double the specified dimension and halve it to use.

Well, I do agree, but since there is cavity wall insulation ( and I will refill this) between the two walls, I hope it is not significant. Originally, I specifically discussed this with the builder and architect, but they put this steel up so fas and unexpected to me that I couldn’t react. I might have asked them to put some mineral wool into the wall through the hole.

The problem is really that all these things are not part of building control and my builder knows exactly what they look for. That is why I am not stressed about the compass foam and other thermal bridges.

The builder is very good with bricks and mortar and he does now seem to take onboard some air tightness measures. Mainly so that he closes holes where he sees them and I talked with him about air tightness paint and have already bought some. However, it is a battle…

and of course finding the structural issues and holes everywhere, puts cold bridges and air tightness on the Blackfoot as I need to sort that first.

As you suggest, you can try reinsulating the cavity where the RSJ work has exposed it and damaged or lost the previous insulation. You could also insulate the length or part of the RSJ nearest the outside wall to reduce the cold effect brought into the conditioned space of the thermal envelope. However you don’t want to isolate the RSJ so well from the house while there is insufficient at the end that it’s temperature in winter is below the dew point.

Very good point. Don’t want to get the steel become a massive conductor for the cold.

I will try to get some mineral wool into the cavity through the sliding door reveal to prevent this. I can look directly into the cavity from the door and the builder has to fit the new lintels there anyway. I will ask him to add insulation before closing it again.

150mm bearing on each side as a minimum.

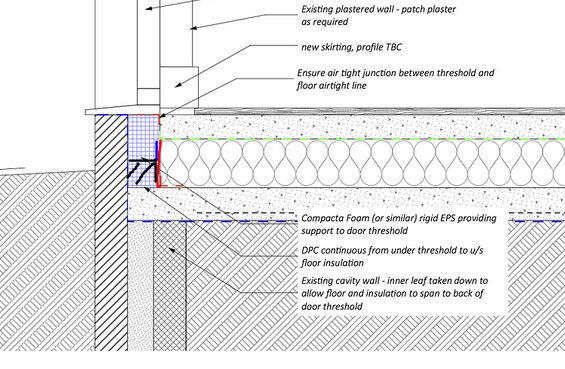

you just need to maximise the continuity of the insulation under the door to the under floor insulation.

If you reduce the depth, you will be slightly increasing the thermal bridge potential. Shown by the black brick i drew and the reduced legth of the blue line compared to red.

If your really concerned about cost. XPS will likely do the job. It is extremly dense and stable in the moist ground condistions.

standard EPS should go nowhere near the ground. I wouldnt even put in the cavity in a non load bearing manner near the ground.

Compact foam is a brand name ususally dense thermoplastic blocks.

alternatly thinner compact foam on top of XPS. XPS has very good compressive strength.

check the compressive strength on the material and the rigidity. compare with the load from the door.

Remember its not jsut the compressive strength, but only ridigity, the compressive creep over time. any flex under the door, after years of repeated use, could result in door opening /sliding issues.

thats whre compact foam excels.

I realise my responses are 2 weeks late. I hope things and progressing smoothly.

The structural engineer calls only require 100mm, but specify a padstone on both sides. Can only do 100mm on the side which goes into the cavity wall as the brick is only 100mm deep.

A architect friend of mine also suggested this stuff called Brigifoam as an alternative that is less costly: https://www.affixit.co.uk/brigi-foam.html?gad_campaignid=9453149258

ahh yeah of course perpendicular to the wall.

Sorry i wa thinking about lintel over door thresholds and the sort. padstones also required.

Any thoughts about how to ‘sleeve’ soil pipes going through an insulated concrete floor?

Building regs say they should be sleeved, but how best to do that and maintain insulation and airtightness through a layer of 100mm concrete, 150mm of PIR and 75mm Screed?

Any suggestions? We have poured the 100mm concrete now and left 20mm around. I am thinking to add some rubber mastic on the bottom and adding Illbruck foam to fill up the rest.

What do you think? And what to do at the next PIR and screed layer? Any best practice advise?