I can later share some of the quotes I am getting including installation if that would be interesting. It certainly is a massive cost and I am particularly looking at the part on how the install is done. It may be well worth spending an extra £1000 for a good installation to ensure they close air gaps and cold bridges rather than working about whether the U Value is 0.8 or 0.9.

Agreed. I have windows that claim Ug = 0.8 and Uf = 1 but the installation was hopeless. The company went bust shortly after I exhausted sensible discussion and lodged a formal complaint so I ended up sealing frames to reveals myself.

Yeah thats true, I guess most of the very qualified in the know installers also supply triple glazing. Or at least the suppliers have a limited number of reputable installers they prefer you to use? Please do share quotes when you can. Keep install costs seperate.

I still don’t have any final window and doors install costs as the manufacturers separate these as well. I also got one for Norrsken, who’s windows were about the same as 21 degrees but they estimated an installation price to be around £5000 plus £1000 for an initial survey and £550 for silicon (Everbuild 825 Mastic). I need to clarify which windows are included for this as I had the quote for several options and asked for bay window panel pricing as well and maybe they have included that for the estimate. This installation cost seems a bit excessive for 2 windows and 3 doors on the ground floor.

Does anybody have a more general idea of install costs? How much per day for a decent installer team of maybe 2? @Tim_Gilbert I was originally thinking this shouldn’t be more than £2-3000 and would take perhaps 2-3 days as it includes a wider balcony door as well.

Another question for anybody here is what kind of paper work and certification would be valuable to get for the work?

Is there anything to get at the end that says the insulation and airtightness is up to scratch? I mean other than keeping a record and journal myself? I am obviously aware of EnerPhit, but when you do things in stages what would people want to see to perhaps build on themselves from? Does the AECB have some intermediate certs or something to increase trust in the work?

Thank you.

The AECB has a 2 step retrofit standard. Step 1 is heat pump ready and step 2 is the full works. I doubt that your windows would be included in step one unless there is Freeform logging of installed measures

I don’t know how current prices are for installation but can well imagine that the shortage of skilled and committed tradesmen/women has pushed prices up.

If it helps, we got 14 double glazed windows (various sizes in a cottage) installed for £8,580.00 plus vat in 2022.

What do you do if you don’t want to start with the heat pump? It seems like the wrong way around and would lead to oversizing the heat pump and then you are locked in with higher energy consumption for decades. That can’t really be the goal, can it?

Do you know if this has to be started with the heat pump? Thanks.

The lower standard is “heat pump ready”. In effect they are saying “don’t fit a heat pump before your house reaches this standard”. They are not saying “now fit the heat pump”.

If you have an efficient boiler with plenty of live left in it I can certainly see that you might want to get more retrofit done before swapping. The BUS grant doesn’t help as it requires a heat pump that meets current rather than projected demand and that demand is always pessimistic.

Aside from the initial cost and the space a large heat pump demands, there is not actually a machanical problem, providing the heat pump can modulate down far enough. If it can modulate down to the new lower demand you have after more refurbishments, you are ok.

The issue is if it can not and the ASHP is constantly switching on and off.

Just to keep everybody in the loop, while I made good progress on windows and doors, I still don’t have a builder for the project. I had two coming over and promising me a quote with a week and still nothing even after more than a month and chasing.

Another one is coming over on Monday.

Unfortunately the Retrofit Coop also can’t support the project.

Although I have to thank @Russell_Selby for helping me in the meantime discussing aspects of the build and learning a lot.

I am even now thinking to get the PHPP model from the AECB and learn it a bit myself. ![]()

If you are thinking of following the PHPP route I suggest that you stop work on the house, get your model sorted and then follow the plan. The last thing you want to do is do something now and then discover it was wrong (like my windows)

It is a good point. @Russell_Selby has already done the PHPP model with me. We even got a plan.

Anyway, what went wrong with your windows?

I had good experience of Everest, having bought their windows in the 1980s and went with them again in 2018. Big mistake. By then they were a failing company with contract staff almost throwing windows into openings and leaving them as they landed, so they were no longer in the top league for efficiency and they were poorly fitted.

A friend and I have stripped off trim to reveal the flaws in installation, sealed the gaps and added airtightness but they still aren’t performing as they should.

Sorry to hear that, but I can feel your pain. Still the issue today. This all comes down to the quality of the installers and whether or not you know to tell them you care about air tightness and insulation and then check up on them.

And this is despite many of them charging seemingly super high day rates, some just optimise for profit alone and they can get away with it because how would you judge the quality once it is all plastered up. They would probably not even feel bad about it as the standard is low anywhere and they just want to offer a more ‘price competitive’ job.

Anyway, I can see that there are certain things you can’t easily fix after the window is sized and installed. But I am really happy we have this forum here to discuss these geeky but important things. Also a big thank you, Tim, for your constant support here. It makes a big difference to people like me.

Ooo. I’m feeling all warm and fuzzy! Thank you for your kind comments.

Hi all, sorry for the long pause, but times are a bit mental at work and with the building project.

The builder has finally started on 7th of July and all my former concrete kitchen and suspended living room floor is removed from the ground floor. Looks scary.

They have also started to remove the Chimney breast on the ground floor and rebuilt the party wall and removed a load bearing wall to open up a kitchen diner area

The speed of demolitions is extraordinary. Less than 8 days and 3-4 guys…

Shouldn’t really be unexpected, but of course I did find some ‘unexpected’ structural issues in my outer wall, where the old conservatory is/was attached… We found that the conservatory was toothed into the outer leave on one side and because they ‘forgot’ to add a foundation under the brick structure it was sinking and thereby pulling my cavity wall apart. So I decided (with suggestions from the structural engineer) the conservatory had to be pulled down to fix the wall. A bit sad, as I liked the space, and of course it costs extra to do all this.

Of course removing the conservatory we also removed all the old plaster on the inside of the conservatory and the outside of the outer wall within that… revealing some significant cracks in the brick wall over the door brick arches.

You wouldn’t believe what you can find under 30mm wet plaster…

This brings me to the first discussion point with you. Door reveals and lintels.

More precisely, thermally broken lintels.

I hope the above is useful to somebody in terms of sharing the retrofit experience. ![]()

In terms of my lintels, there is basically a brick arch over the outer leave and a wooden beam on the inner leave on both the doors you can see there. Apparently quite standard for houses in 1945. Not something I thought much about on my project, but maybe I should have when aiming to replace the doors with triple glazed versions to fix heat loss and air tightness… oh well.

Of course I discussed with my builder some new lintels to fix the cracks and when you start thinking about it, you then think about thermally broken lintels, rather than the usual steel stuff every builder will grab to just replace things. Creating a cold bridge in doing so.

So I am currently discussing thermally broken lintels with my architect and asked my structural engineer to spec them for me. Of course then my architect also reminded me to think about a cavity tray above… which currently doesn’t really exist.

So I am in the middle of thinking this through and hopefully my structural engineer can directly spec this, but my architect warned me that these are not yet really standard so might cost extra and cause delays.

Moreover, I will probably have to explain this to my builder again, who is generally very good but not an expert with insulation, airtightness or thermal bridging. So he would not cost such things ( as it is not standard). Hence, I have to become an expert to be able to explain it and also be sure what the best thing would be without paying too much extra for ‘custom’ work for something that should be standard.

Do you have some expertise with thermally broken lintels for a cavity wall with a 50mm cavity? Would you go for a thermally broken lintel, or perhaps two separate lintels, one for the outer and one for the inner leave?

Final discussion/ question for you tonight is about the door thresholds.

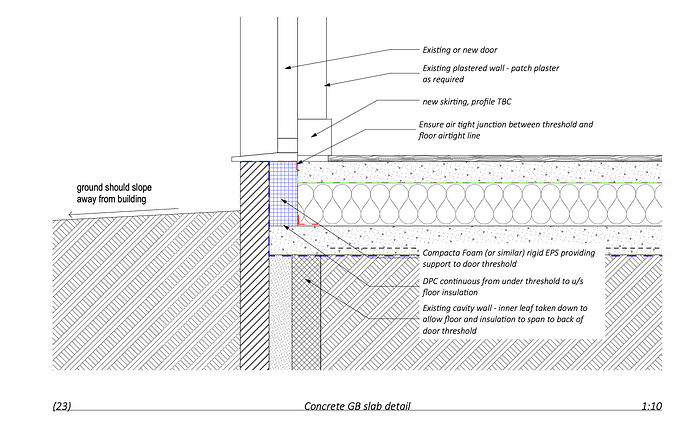

My architect specified the following and reminded me and the builder that I should get the compacfoam ordered in time as this could take some time.

While I specifically talked about this with the builder at some time point, and he said that is what they do anyway. I don’t really think he realised the need for the compacfoam and neither am I sure if he has used it before.

When reminding him, he asked if he could just use 25mm PIR… So at this point I am unsure what he is thinking.

So I am currently trying to find the best way of understanding this and being able to explain why to my builder. The architect drawing seem to spec a 225mm high piece of compass foam, which is not a standard size available. So I am now getting into custom formats that I assume will be more costly and longer time to make.

So far, my research today (using mostly Grok) and it mostly suggests that while builder may use some structural EPS like compacfoam under door thresholds, but usually only as a 50-100mm thermal break or something. Larger blocks are not usually cost effective for new houses etc.

However, I am struggling how this build up would look like as I haven’t yet found any good drawings to see what is done as a standard. I need to understand what the standard looks like as the builder will very likely refer to this first and ask why the drawings spec this extra ordinary piece of compacfoam.

Moreover I need to know/ decide fast to get the right things going as I think the concrete will be poured in 2 weeks or so and then the insulation comes next. Thanks. Any sources and explanations would be greatly appreciated.

Also as a note that the doors will be from Nordan and their threshold is about 113mm and 172mm (for the sliding door), so they definitely sit not just on the outer leave, but also go over the cavity and the inner leave.

Currently the door thresholds look like this… with the inner leave largely removed as that was crumbling anyway.