Anyone tried insulating existing hardwood doors? Well insulated Green Building Store doors would require a wider doorway to get the same opening width. So quite a bit of building work required.

Thanks, Phoebe

I’m about to do this one. The inside has 25mm recesses between cross planks that I intend to fill with 25mm PIR board which I’ll top off with some foil and then thin ply to gloss piant over.

Thanks for sharing this. Please would you kindly share a photo of the work in progress (inside) so we can see how it works out. Looks interesting.

@pwshk , Getting shaped insulated doors is virtually impossible so insulating the one shown is a good idea. If it isn’t too late I suggest finishing off not just with thin ply but a layer of all covering insulation, otherwise you will end up with a very cold door along the structural timber (thermal bridging). You could put PIR then board or buy pre-insulated flat roof board. The frame can then be finished off the same way to maintain the same levels inside and reduce thermal bridging at the frame.

@Tim_Gilbert - still got this to do, thanks for the steer.

Finally getting around to this job… filling the recesses in ths old door. I’m wondering if I can layer-up with the likes of prowarm or similar UFH insulation rather than using 25mm PIR and still get decent insulation? I figure the thinner materials will be easier to cut with my skill level!. Still intend to top as suggested by @Tim_Gilbert

Layering is sometimes a good idea. Are the areas to infill a multiple of the depths of either insulation product?

I am inclined to discount Profoam as there is no declared insulation value.

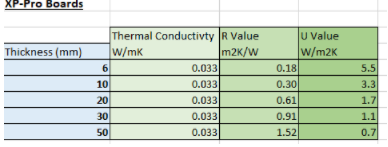

Arbiton, on the other hand has an R value. The U value of the installation would be 1/xR, where x is the number of layers (ignoring the value of the door itself).

Edit: Reviewing the image, R<0.8 is too vague. Zero is less than 0.8. Try to find a thin enough product with a properly defined U or R value.

Thanks Tim. 4 * 6mm layers of this should do the job. W/(m .

K) 0,035 - 0,037.

My recesses are ~25mm so with adhesive this should be ideal when topped-off as you suggested. We’ve also decided to blank and fill the letterbox and install an external wall mounted box.

Just need a tidy solution for the keyhole and we’re sorted.

How many layers of insulation are you planning on top? Check the length of your keys and the door handle spindle. New spindles (if that’s the correct name) are easy to buy but you may need to get new, longer, keys cut. Long screws may be all you need to fix the handles, although they would cause a thermal bridge.

4 layers for the recesses and a thinner layer (might just be foil type barrier) all over the door plus the plywood topping for a paintable service. Ideally <6mm for the lot. More concerned about weight than thickness. I have ~15mm of key shaft exposed.

Looking good.

It isn’t usually possible to effectively insulate a keyhole, you may need to just find a (nearly) airtight cover to keep draughts out. If you fit them on both sides of the door you won’t get a draught while using the key, as one will always be in place.

First layer (finally) in the recess and the difference is very noticeable at the end of the hall. 3 more layers to go then top finish to sort.

It may not suit your colour scheme but I think that door has character.

Try staggering the joins to reduce bridging.

Fair to say that the lilac insulation has not gone down well with all… once the ply is on and glossed we’ll be grand.

Yes, I’ll alternate the joins to avoid any bridging. Very pleased with the improvement after just one layer