My Vaillant Arotherm+ heat pump has been providing me with heating and hot water for about 3 weeks and on Tuesday we set up an overnight setback period for heating and a legionella cycle for the DHW.

The setback period is 11pm to 5am, and were going to set the legionella cycle to run at 11pm on a Wednesday. Somehow the installer rescheduled the legionella cycle for Monday afternoon instead! I’m still on a fixed tariff, so time of day makes little difference at the moment.

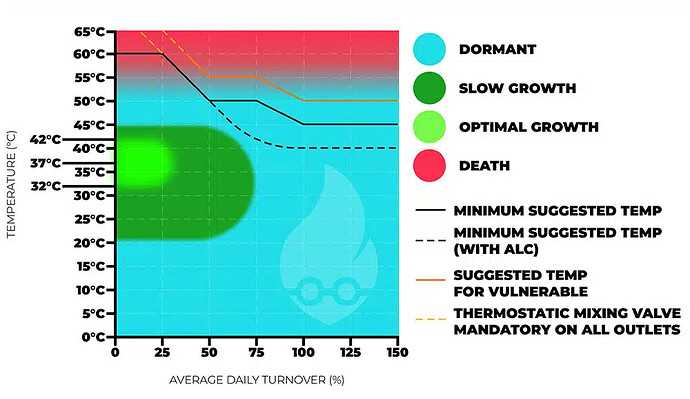

But before I try changing it back, I’ve been looking at the hourly hot water temperatures downloaded from the My Vaillant app, and referring to the HeatGeek diagram on Legionella and Water Temperature: What You Need To Know.

I use very little hot water, and the hot water cylinder has been sized at 200 litres for the potential future occupants rather than current occupants, which I understand.

The normal setpoint DHW temperature is 42 degrees and it’s set to automatically reheat when the tank temperature drops by 10 degrees. So without running a legionella cycle it spends most of its time with the hot water at between 32 and 42 degrees, which provides ‘optimal growth’ for the legionella.

The Vaillant legionella cycle heats water to at least 60 degrees for one hour. It can be configured for any day of the week, but the frequency is fixed at weekly and the temperature is not configurable.

Since I’m an ‘older/more vulnerable’ person, I am advised to store water at a high temperature, while at the same time avoiding scalding!

Routine water heating can be automatic - when the tank temperature drops to a certain number of degrees below the setpoint temperature, or scheduled for certain times/days (haven’t explored parameters for this yet), or there’s a manual setting.

Is anyone else in a similar situation, and if so have you found a solution to keeping the bugs under control/avoiding scalding/minimising cost of hot water?

I’m curious whether anyone else on here is in the same situation? And whether they have found a good way around it.